Hands up if the following scenario resonates with you and your organisation.

A CEO and their team are battling on all fronts. Service level issues lead to a decline in sales, while the COO grapples with enhancing the Supply Chain and the CIO navigates the complexities of upgrading from SAP R/3 to S/4.

Amidst the chaos, buzzwords like AI and digitisation promise miraculous solutions. Yet, embarking on complex journeys with unproven solutions raises questions. Do you have the resources and time, especially amidst tightened budgets? Many feel the known improvement levers have been exhausted and are considering alternatives to traditional consulting and business transformation models.

Many will recognise this situation… A salesperson secures a €70k order and needs it urgently. But the order can’t be delivered because Logistics are unable to organise the extra truck, (costing €300 over the norm), because Procurement will get a slap on the wrist if they do not stick to the single-source, as-cheap-as-possible supplier policy.

Result: No sale, Customer unhappy (bad service), Sales unhappy (didn’t make the sales revenue), CEO unhappy (was dragged down in the day-to-day operations with the complaint of an angry customer), CFO unhappy (lost revenue), Head of Supply Chain unhappy (got blamed for something outside their control), Procurement unhappy (stuck to their objectives and guidelines but then got blamed for it).

Meanwhile, that same salesperson can ship €20 worth of products on a Europallet (at €14 per pallet plus transport cost) because the company struggles to connect end-to-end costs (and hence put a stop to such deliveries), despite utilising a purportedly best-in-class ERP system for over 20 years.

Is AI the solution? At AB Advisors, we believe there are still quite a few classic levers left to improve a company’s performance in a pragmatic way. But why does the old approach, and pulling the known levers, not work anymore? How did we get in this ‘perfect storm’? First, we must understand the past in order to steer into the future.

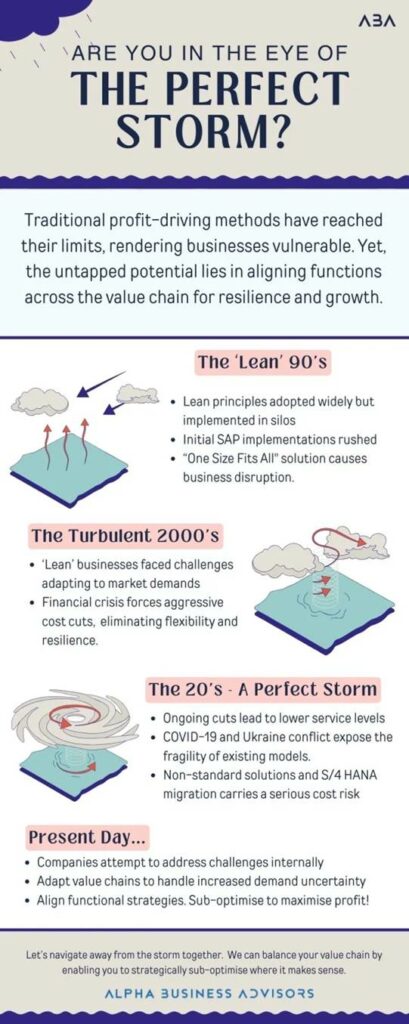

The Perfect Storm

The 1960s and 70s saw the emergence of the Toyota Production System, a philosophy aimed at streamlining processes and eliminating waste. It wasn’t until the 1990s and early 2000s that these principles, now called “Lean”, gained widespread adoption, albeit in a rather limited scope focused primarily on cost reduction, minimising inventories, and maximising asset utilisation (Overall Equipment Effectiveness – OEE). Often trying to achieve each of these in silos, creating islands of best practice, but then failing to reach the optimal result for the overall company. Still, in the initial phases, there was “fat to cut”. This period also marked the first significant wave of SAP implementation, driven by two key factors:

- The urgency to meet the Y2K deadline

- The drive to harmonise to one set of best-practice processes.

Organisations, in their haste to meet these deadlines, often implemented changes unilaterally (helped by a school bus of Big-4 consultants), leading to a ‘one size fits all process’-approach. The drive to get Lean, exacerbated this drive to standardise which often overshot its objective.

Post-2000, the repercussions of this overly ambitious standardisation became evident. Businesses found themselves often unable to adapt to market demands anymore, having given up unique practices that once gave them a competitive edge. The fix was the proliferation of exception processes and customisations of the SAP system. Consequently, for the next 15 years, any talk of standardisation or harmonisation was virtually taboo.

Although most companies had adopted Lean, businesses did still maintain strategic contingency plans, trying to ensure they could react to certain “what if scenarios”. The 2008-09 financial crisis would bring an end to this too. Businesses were pushed to cut costs aggressively, often at the expense of this last bit of operational resilience. The once-prevalent model of having at least some contingency plans was now perceived as an unnecessary cost.

The new operational ethos centred on a singular best practice approach, leaving businesses vulnerable to disruptions and unable to cater to the growing market fragmentation and demographic shifts, such as the emergence of new geographical markets, Gen Z and the Silver Generation in an efficient way.

One of the side effects was cost creep, as the one-size-fits-all lean operating model and processes would be flanked by a parallel world of (hidden) exceptions, unsanctioned workarounds, or bypasses to the best practice processes.

By 2020, businesses faced a critical juncture. The relentless drive for continuous improvement had pushed the operating models to (and often over) their limits, with further functional optimisations often only leading to

a. deterioration of Service Levels and

b. a stagnation of the performance improvements.

And now the disruption happened… COVID-19 and the conflict in Ukraine served as catalyst(s), revealing the fragility of the existing operational models and pushing the Value Chains of many businesses over the breaking point. Many hoped for a return to “normal,” but meanwhile, many have realised we are in a “new normal” that leaves executives with questions and problems they have never faced before.

To add to the challenge, the compulsory migration to SAP’s new S/4 HANA version necessitates a re-evaluation of these accumulated exceptions, forcing business leaders to think about eliminating certain options in the value chain. But faced with the current uncertainty, which one do you eliminate?

Especially in an economy where every wrong decision, however small, is being punished straight away and where every CEO, COO or CFO is judged on the performance of his last quarter.

As a result, we often see paralysis. Businesses hesitate to start projects, especially as they realise the traditional consultancy approach focused on “improvement within the function” and “delivering known solutions” no longer suffices.

Every Senior Leader we talk to says we need a step change. But which way do we go? Do we jump on the bandwagon of unproven digitisation and AI solutions that promise to solve world hunger? Radical change is necessary, but such changes are also often perceived as overly ambitious and financially daunting, especially in a climate of tightened budgets. Or, are there still some traditional levers we could pull to generate step improvements in an environment that still is somehow familiar?

At AB Advisors, we believe one solution that is still considerably underutilised is aligning functional strategies, hereby accepting a degree of sub-optimisation but enhancing overall corporate performance. This does involve adapting value chains to accommodate the increased demand variability, hence building in “fat” again, a way of thinking often outside the traditional corporate way of measuring people’s performance.

Faced with the lack of a fresh approach on the side of the traditional consultancies, we see that many companies are attempting to resolve these challenges internally but are often constrained again by the same traditionalist thinking and hence keep struggling with making progress.

Why AB Advisors?

Our expertise lies in delivering innovative yet pragmatic solutions to seemingly complex challenges. We bring together individuals with years of hands-on experience who know the details yet still have the ability to see the bigger picture.

In many companies we work with, we uncover inefficiencies stemming from obvious yet unaddressed causes, as illustrated in the case example at the start of this article. To resolve these issues, a deep understanding of company dynamics, human behaviour, and value chains is essential.

Our team excels in simplifying complexities, demonstrating that simple and elegant solutions can reduce inventories and supply chain costs while enhancing customer service. Moreover, we are passionate about sharing our knowledge to empower your team to develop and build a more resilient business.

We firmly believe in the power of human intelligence, and there is plenty in your organisation! It is important, however, to align human efforts across all levels of your organisation. Investing in solutions like AI is futile if internal teams are not synchronised.

Balance is a keyword. Simplicity is another one. With the right chef in the kitchen, even a simple omelette can be made into an exquisite dish. The obvious one is that a leader needs to dare to make decisions. You cannot make that omelette without breaking eggs.

Balance and simplicity are our guiding principles. With the right chef in the kitchen, even a simple omelette can be made into an exquisite dish. And the obvious one: a leader needs to dare to make decisions. You cannot make that omelette without breaking eggs.

When you partner with us, we dare to go back to the basics. We analyse the overall picture, identify root causes of performance issues, and develop a pragmatic roadmap for change. Our focus is on incremental improvements, starting with quick wins, to pave the way for broader rollout of an operating model attuned to the new realities of the business world.

Let’s discuss how your organisation is navigating the challenges posed by the Perfect Storm and explore strategies for addressing them.

0 Comments